We’re not going to sugarcoat it. Welding can be a dangerous activity when safety precautions aren’t followed.

Welding machines like MIG and TIG welders and tools (like plasma cutters) can present many hazards to both those actively at work and those in the vicinity. It is crucial to be aware of all the risks and dangers of welding, and understand what welding safety precautions need to be taken to protect welders and those around them.

The good news is that following welding safety rules isn’t hard. In this guide we'll help you understand all of the major aspects of staying safe while welding.

Overview:

- Why Is Safety Important in Welding?

- What Are the Main Hazards in Welding?

- Essential Welding Safety Equipment

- Keeping a Safe Workplace

- What Are the OSHA Requirements for Welders?

Why Is Safety Important in Welding?

Safety in welding is crucial because there are a lot of potentially dangerous elements at play.

Even experienced welders can have lapses in judgement that can put them, and those around them, at risk.

What Are the Main Hazards in Welding?

The main hazards in welding are the following:

- electrical shock

- fire and burns

- radiation

- toxic fumes

- hearing damage

- vision damage

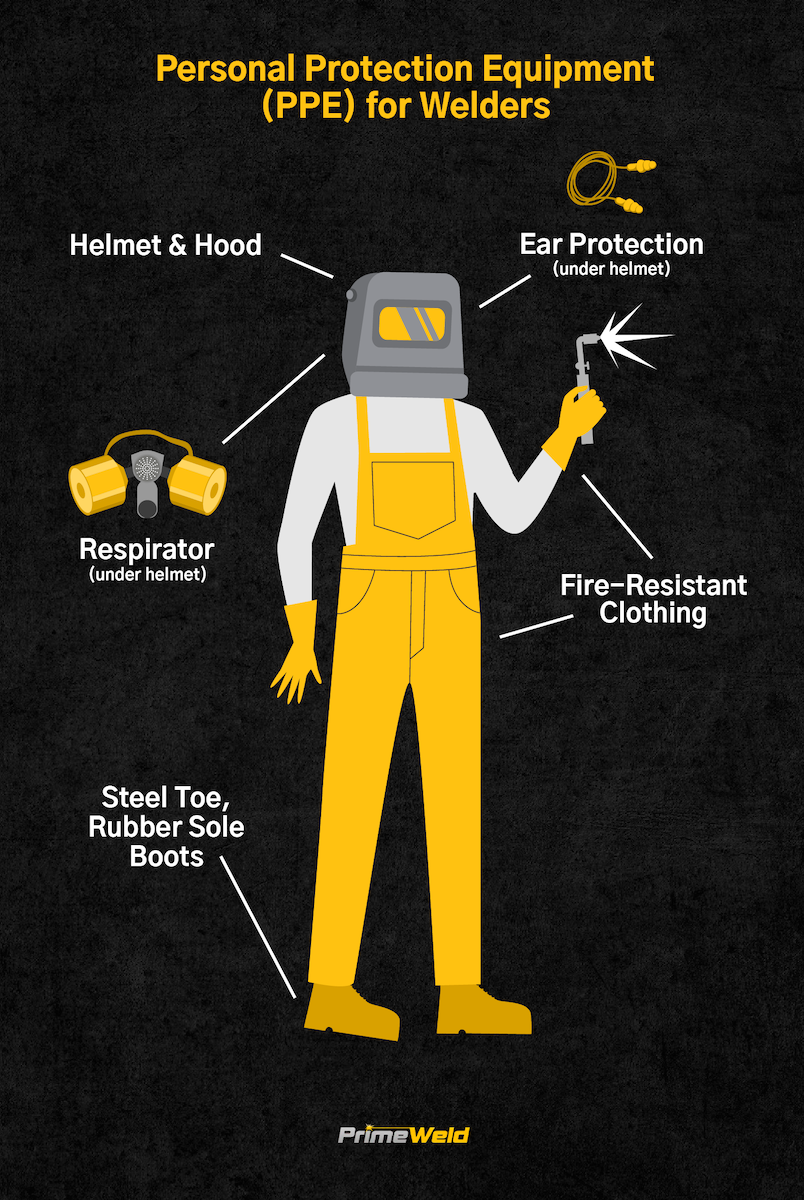

This graphic explains the primary safety measures we take to address each of these hazards:

Electrical Shock

Though exact voltage varies by machine, welding machines have a lot of electricity running through them while they’re turned on. If part of a welder’s body creates an arc or bridge between the welding supply and return, the welder could be shocked or electrocuted.

A properly grounded welding machine should have little to no risk for a welder, so ensure that machines are properly set up. After all, just 100 milliamps of electrical current can be fatal.

Fire and Burns

It should be pretty obvious that welding produces both heat and sparks. When proper precautions are taken and the right tools are used, this isn’t a problem for welders. However, sparks especially can fly and land on flammable materials such as rags or cardboard boxes, creating fires.

Additionally, burns are possible when handling materials that are 10,000 degrees Fahrenheit (a typical arc welding temperature) or 50,000 degrees (for plasma torch welding). To put that in perspective, frying grease is only 300 to 500 degrees and can cause severe burns.

Exposure to Radiation

Arc welding produces extremely high-intensity light, and anything that produces light also produces ultraviolet (UV) and infrared (IR) radiation. UV radiation can cause sunburns and, eventually, skin cancer. IR isn’t as big a risk to welders when proper eyewear is used.

Exposure to Gases and Fumes

Common gases used and produced in welding include argon, nitrogen, carbon dioxide, carbon monoxide and hydrogen fluoride. Though these are mostly gases we breathe in small amounts every day, welders are around them in much higher concentrations than can be healthy.

In enclosed spaces, inhalation of these gases and fumes can cause nausea, dizziness, and irritation of the eyes, nose, and throat. They can even cause death, especially carbon monoxide.

Some metals are coated with zinc, cadmium, chromium, copper, fluoride, lead, manganese, or vanadium (which can cause metal-fume fever) that present flu-like symptoms, after as little as four hours of exposure to these materials.

Hearing Loss and Damage

Welders are at an increased risk for hearing loss, not just due to the decibel levels produced by welding and cutting (plasma cutters can easily hit 100 dB), but by the fumes associated with welding. A study showed that workers exposed to noise and manganese together suffered more severe hearing loss than those exposed to manganese alone.

Inhaled manganese from the fumes produced through welding in particular, can be harmful to hearing. That’s because it’s transmitted directly to the brain before being metastasized by the liver, causing nerve damage that leads to hearing loss.

Eye Damage

Any type of UV exposure can damage the eyes, and traditional sunglasses don’t offer as much protection for welders as they do for everyday uses. In fact, welders are diagnosed with corneal flash burns so often it’s called “welder’s eye.”

Essential Welding Safety Equipment

Ensuring welders are wearing appropriate protective gear is an important step in welding safety. Welders should wear clothing and gear that will both protect them from the heat, sparks, fumes, noises, and UV radiation created through welding, at all times. Employers must keep this gear available to their welders.

Personal Protection Equipment

Proper safety equipment (PPE) worn by the worker is the first line of defense in preventing welding accidents and damage from UV rays, burns, fumes, or noise.

This includes the need for properly sized PPE for the growing number of female welders. Improperly-sized welding PPE still provides some protection, but it can be harder for smaller welders to move and see well enough to do their work safely. Those who employ welders should be sure to keep the appropriate sizes of helmets, gloves, jackets, etc., to keep their workforce safe.

Helmet and Hood

A helmet with side shields will protect a welder’s face and head from UV radiation, chemical burns, loose particles, debris, and hot slag. Welders should never remove their helmet while working, nor while watching a fellow welder work.

Most welding helmets are adjustable but when in doubt, talk to welders to ensure they have a helmet that fits them.

With auto-darkening welding helmets, be sure to keep the necessary batteries handy, as these helmets aren’t passive and thus require a power source.

Welders should also make it a habit of wearing a fire-resistant hood under their helmet. It might not be the most comfortable thing to wear when it’s warm in a workspace, but a hood protects the neck, ears, and back of the head from injury and exposure.

Eye Protection

Though welding helmets provide some protection for the eyes, most companies now require the additional step of wearing protective eye goggles under one's hood as well. This double protection reduces the risk of catastrophic eye injuries.

Every welding shop should have eyewash stations that welders can get to quickly — within 10 seconds. Every second counts when toxic substances get into a person's eyes.

Respirator

While proper ventilation goes a long way, not all welders have the benefit of working in the open air. For example, welders employed on ships or in shipyards don’t have the benefit of open-air workspace.

Wearing a proper respirator will protect welders from gases, fumes, and oxides that form when using a welding machine like MIG or TIG welders, or a plasma cutter. Welders must select a suitable respirator for the project type they are working on for maximum lung safety. Welders also need to ensure that the respirator fits properly.

Protective & Flame-Resistant Clothes

Wearing fire-resistant clothing will protect welders from heat, radiation, fire, and burns that a welding machine creates.

Never wear synthetic materials (e.g., nylon, acrylic, and polyester) that will melt onto the skin when hot. Leather or cotton treated with flame-retardants form a great protective barrier.

Gloves need to be insulated, and flame-resistant. Boots should have a rubber sole and a steel toe to protect welders from electric shock or fallen objects.

Ear Protection

Some applications (like using a plasma cutter) have consistent decibel levels of well over 100 dB. To put that in perspective, hearing loss can occur with just 15 minutes of exposure to 100 dB and people can experience hearing loss after less than two minutes of exposure to 105 dB.

Ear protection is important to dissipate loud noises to prevent permanent hearing loss or damage that causes tinnitus, high blood pressure, or vertigo. Fire-resistant earmuffs can be worn to keep sparks or metal splatter from entering the ears.

Keeping a Safe Workplace

Keeping safe welding equipment handy is important for each individual welder, but it’s nothing if the working environment isn’t also safe. Here are some tips to ensuring a welding workspace is as safe as possible.

Eliminate Flammables (Fire Safety)

Fire-resistant clothes will keep welders safe from their clothes catching fire, and the same care should be taken to prevent fire in the surrounding areas. No combustibles should be present within 35 feet of the work area. If a combustible material cannot be moved from the area, set up a fire-resistant shield to block any potential sparks.

Holes and cracks in the floor or walls should be investigated for potential combustibles as well, since sparks can fly everywhere. A fire extinguisher should be nearby to welders.

Finally, whenever welding or cutting is performed in locations where other than a minor fire might develop, a person should always be standing watch with a fire extinguisher in case a fire breaks out in the area. Additionally, a welder or an assistant should watch a workspace for 30 minutes after welding has finished to ensure no smoldering fires break out.

Ensure Proper Ventilation (Respiratory Protection)

Ventilation is key for keeping welders safe from fumes and gases produced through welding. If an open area isn’t possible, local exhaust or general ventilation systems should be in place in addition to respirators worn by welders.

Chemical Safety

Sometimes welders have to weld or cut chemical containers. Before work is done on anything that has been in contact with grease, tar, acid, or other flammable or combustible materials, those containers must be thoroughly cleaned of potentially toxic or explosive materials.

Cylinder Safety

Cylinders used to store compressed gases must be labeled and properly stored. This means stored upright in a rack or tied together. Additionally, not-in-use valve caps and hoods should be employed to prevent leakage.

Cylinders should never be dragged or lifted in a sling. This practice carries the risk of damaging or dropping the cylinders which could cause them to burst. Instead, roll cylinders on their bottom edges or use a hand cart to move them.

Electrical Safety

To ensure electrical safety for welders, it’s essential that welding equipment is properly grounded. However, even properly grounded machines can be dangerous in wet and humid conditions like shipyards.

To decrease risk of shock and electrocution, insulate conductive parts and have welders wear dry gloves and protective footwear.

Access to Material Safety Data Sheets (MSDS)

Every product used by welders has a corresponding Material Safety Data Sheet (MSDS). A product's MSDS describes potential dangers, necessary precautions, and exposure limits.

Welders should review the MSDS for each product before working with it. Following the recommendations in the MSDS should prevent accidents or dangerous exposure to toxic fumes.

What Are the OSHA Requirements for Welders?

The Occupational Safety and Health Administration offers both guidelines and requirements by which welders and their employees must abide.

- 1910.252 General Requirements, Welding, Cutting, and Brazing

- 1910.253, Oxygen-Fuel Gas Welding and Cutting

- 1910.254, Arc Welding and Cutting

Whether you’re employing other welding professionals or are welding in a personal workspace, it’s essential that the guidelines set by OSHA are followed to keep welders and others safe.

Though welding can be a dangerous activity -- from fumes to fires -- it can and should be as safe as an office job. As long as welders abide by regulations and best practices, have properly set up and maintained equipment, and appropriate PPE, they can have long and healthy careers.

Leave a comment 0 comments, be the first!