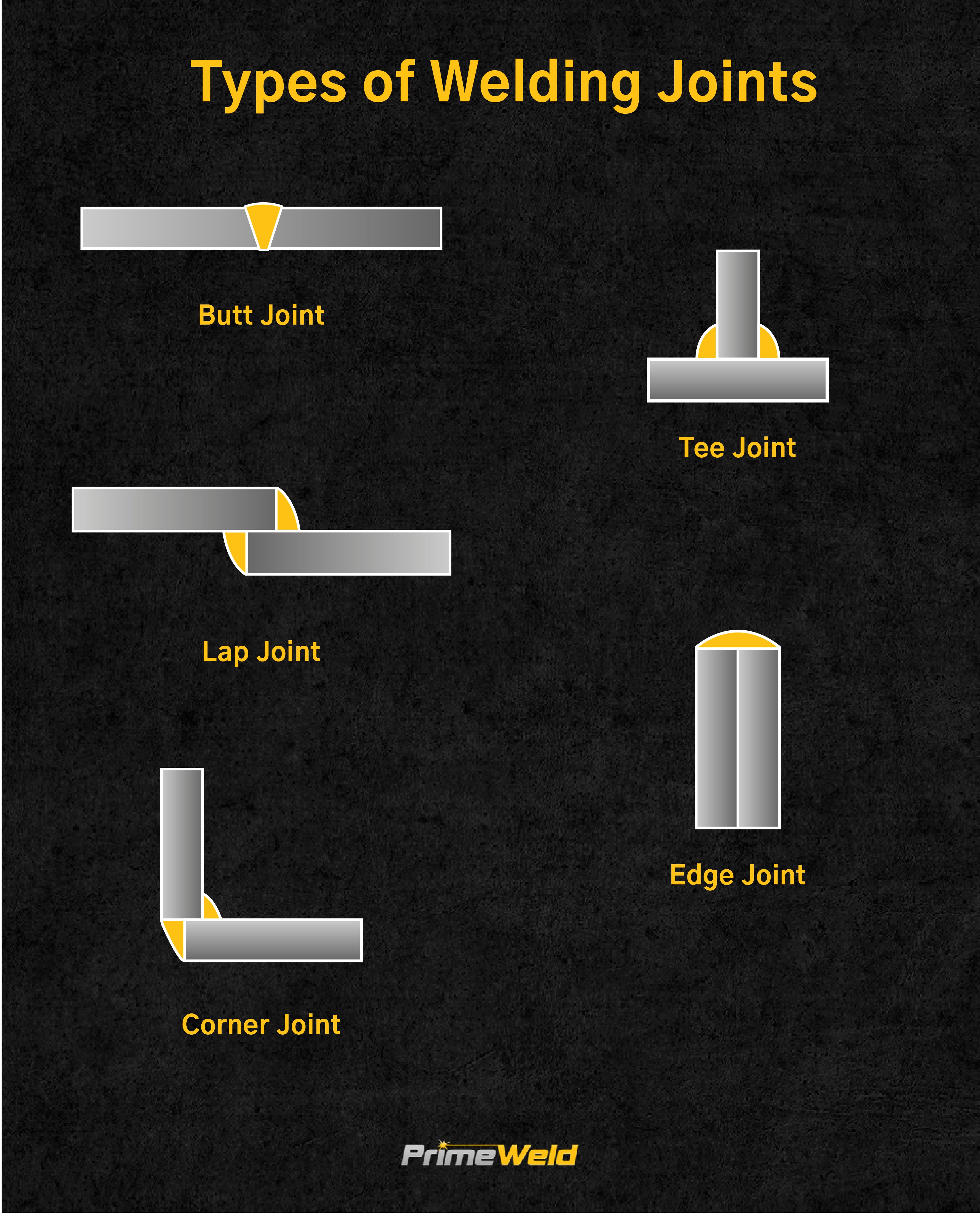

This guide will cover the 5 basic types of welds and weld joints, the pros and cons of each, and the possible different applications for each.

The Difference Between a Weld and a Joint

Before we go further, it is important to point out that types of “joints” and types of “welds” are not the same thing, and it is incorrect to try to use these terms interchangeably.

Joints are the points or edges where two or more pieces of metal are brought together to achieve a desired shape or structure.

Welds refer to the weld configuration used to weld the pieces of metal within the joint and make, effectively, one completed part. For example, the commonly used fillet weld could be used to weld a lap joint, corner joint, or T-joint.

The 5 Basic Weld Joints

Let’s take a look at each different type of weld joint, describe what it is, how it might be utilized, and the possible pros and cons of each.

Butt Joint

Within the butt-joint classification, there are a number of variations on the design of butt joints based on edge preparation of the two elements of the joints, including;

- Square

- Single bevel

- Double bevel

- Single J

- Double J

- Single V

- Double V

- Single U

- Double U

- Flanged

- Round edge (single flare and double flare)

Square Butt Joints

A square butt joint would commonly be used on thinner sections of a plate, tubing, angle, or channel, i.e., ¼” or less, and are not under tremendous amounts of stress. These joints require virtually no joint preparation to speak of; merely fit the pieces together with whatever gap suits the chosen welding process and requirements of the task involved, and start welding.

Single Bevel Butt Joints

A single bevel is where only one of the pieces to be joined requires a bevel to achieve the desired weld penetration. This is commonly used when welding beams to columns in the structural steel construction industry. It would not be practical, or even possible, to bevel a column in the vertical position so the joint prep is performed on the beam only. A single bevel in this application allows the welder to weld the entire joint from one side. This is advantageous where access to both sides of the joint may not be possible. A backing bar may or may not be required, depending on the joint design.

Double Bevel Butt Joints

A double bevel, on the other hand, can be advantageous for this very reason; no backing material is required. The welder may simply weld from one side and then clean the root pass from the opposite side and achieve complete joint penetration this way. Double bevel weld joints are commonly used on pipes to join pipe sections and achieve complete joint penetration which is required for process piping. The beveling can be easily accomplished with an angle grinder for smaller pipes or a beveling machine, a commonly used tool in the pipe trades.

Single V Butt Joints

Single V butt joints are mainly used in joining pipes together where welding occurs from only one side, especially for pipes lower than 24” NPS. In this type of joint, the root pass can be welded with GTAW process or by SMAW process using cellulosic electrodes like E6010.

Double V Butt Joints

A double V bevel can also be used for joining heavy sections of plate or beams together where there is access to both sides of the joint. Again, the bevel can be achieved with flame cutting or grinding and is commonly used in field welding applications for this reason.

J Bevel and U Bevel Butt Joints

Both the J bevel and U bevel joint designs, both single and double bevel, are often found in very specific and unique applications within the welding industry. Both types of joint designations usually require machining of the parts to be joined and are therefore more difficult to perform on job sites. These particular joint designations might be used in joining heavy plate sections or pipe together where the welding criteria is critical. Double U or J bevel can, in rare and specific cases, be used on pipe as a way to counter any possible flow restrictions created by a weld penetrating into the pipe.

Single and Double J & U Butt Joints

Both types of joint designs are mainly used to join thick sections when joints are subjected to dynamic loads, like in the case of bridges. One of the disadvantages of these joint designs is the need for special tools for edge preparation to get the J or U groove butt in the other side. One advantage of these two joints is that they require lower quantities of welding electrodes to complete them, compared to single and double V groove joints.

Flanged Butt Joints

This type of joint design is used in joining thin sections together and is usually used in HVAC duct fabrications where seal welds are required.

Tee Joint

The tee joint, or T joint, is a very commonly used joint in construction and manufacturing across the world. The T joint can be used to join all kinds of different sizes and shapes to achieve the desired end product. For example, attaching the mounting frame to the back of a loader bucket is accomplished with some variation of a T joint design.

The T joint configuration could be welded with either a fillet weld or with groove welds, either partial joint penetration (PJP) or complete joint penetration (CJP) and maybe compound welds including groove and fillet welds like in the case of welding built-up sections.

Corner Joint

The corner joint is very simple and easy to implement and requires minimum prep. The pieces to be joined are brought together at approximately a right angle to each other and tacked into place.The corner joint may be aligned with the inside edges of each piece lined up or with one piece overlapping the other, depending on joint design as shown in the image below.

The corner joint could be welded with fillet welds or groove welds. As seen in the above image, both joints C and D would be a groove weld scenario when performed from the outside but would entail a fillet weld on the inside portion of the joint.

Lap Joint

A lap joint is made by effectively laying one piece (typically a plate) over top of another. As with corner joints, a minimum of joint prep is required to achieve a proper lap joint. Make sure the material is clean and free of dirt and debris, bring into firm contact, tack, and start welding.

Many tank floors are built this way because the lap joint, with a specified amount of overlap, (typically 1½” to 2”) creates a strong joint that can be welded quickly with fillet welds at all connections. This type of joint design is very common in brazing, where the filler wire is melted and left to spread between the two laying sheets or pipes by what is called capillary action. This is used in the joining of copper pipes in HVAC systems.

Edge Joint

Lastly, the edge joint, which is made by joining pieces, usually plate and welding the outer edges. There are several different types of edge joints:

- U groove

- V groove

- J groove

- Corner flange

- Bevel groove

- Square groove

- Edge flange

Edge joints may be made by any of the variations found in the illustration above depending on the thickness of the material to be joined and desired strength of the part being fabricated. Edge joints are very commonly used in sheet metal applications. The edge flange and corner flange are ways to add structural rigidity when using thinner materials.

The edge joint configuration would always be made with some variation of it in the groove weld.

Weld Joints FAQ

Here are some of the most commonly asked questions regarding various weld joints.

Which type of welding joint is the strongest?

It would be difficult to give a one-size-fits-all answer to this question because of the many factors that figure into this answer. First of all, how exactly would you measure strength? Tensile strength? Yield strength? Ductility? One could compellingly argue that full penetration when properly performed is one of, if not the strongest joints. When properly performed, this weld joint should be stronger than the metal being joined.

Which type of welding joint is the most commonly used?

Again, it’s tough to give a simple, all-encompassing answer here. In pipeline construction, you will rarely see anything but full joint penetration butt welds being used. If you work in structural steel, you may see a lot of fillet welds, with only a few butt welds in column or beam splices. If you weld in the sheet metal market, you might see more corner and edge joints.

Which type of weld joint is the most difficult to weld?

The double-bevel butt weld-on pipe may arguably be the most difficult to make for several reasons. One, the weld is typically only accessible from the outside of the pipe. Secondly, the acceptance criteria in the welding codes that typically govern complete joint penetration welds on pipe are very strict and do not allow much room for error. The welder must be able to produce a uniform weld, relatively free from defects from the outside of the pipe with consistency, often in less than ideal conditions.

What are some problems or drawbacks to some more commonly used welding joints?

When performing a butt weld on either pipe of a beam, alignment becomes a very important consideration. Most welding codes allow a MAXIMUM of ⅛” inch of misalignment, some pipe codes may only allow 1/16”. Too much misalignment can adversely affect the quality of the weld itself and the strength of the piece being welded.

It's important to note when using a T joint to join radically dissimilar thicknesses of material together, for example, a piece of 5/16” plate to a 1” section of the plate, there can be stress created at the weld, usually at the toe of the thinner piece being joined. This can be mitigated by either increasing weld size to dissipate the stress over a larger surface area or, using a “repad” which is, in essence, a plate fit between the two pieces being joined in the T joint. This acts as a buffer and seems to dissipate the stress more evenly throughout the weldment.

Photo: Image courtesy Rizky Nuriman.

Leave a comment 0 comments, be the first!